Twin Building

Create and Deploy Digital Twin Models

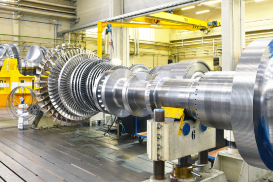

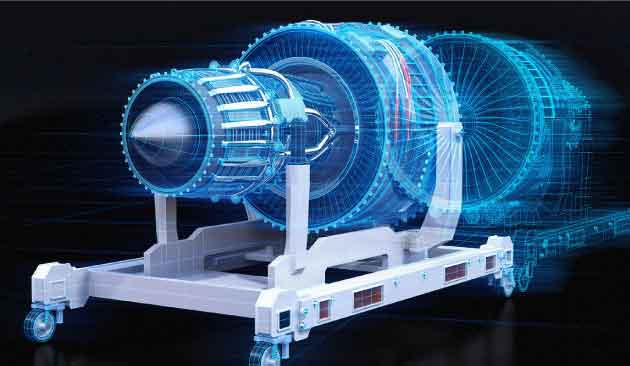

A digital twin is a powerful, evolving virtual model that mirrors a physical asset, process, or system in real time, enabling smarter decisions, predictive insights, and optimized performance.

By integrating IoT sensors, AI-driven analytics, and high-fidelity simulations, it creates a living digital counterpart that continuously learns and adapts along with its real-world twin. Digital twins are not just monitoring tools; they are transformative enablers for industries, driving efficiency through predictive maintenance, performance optimization, and virtual prototyping while reducing costs and accelerating innovation. Scalable across applications: from single components to entire factories, they empower engineers to simulate “what-if” scenarios, validate designs faster, and maximize operational uptime, making them indispensable for next-generation engineering and smart manufacturing.

Fast-track your digital twin success with expert implementation. Telled provides the tools, integration, and industry know-how to turn simulations into real-world results, optimizing performance, predicting failures, and accelerating time-to-value.

Applications

Products

Telled offers advanced Ansys-powered simulation tools for structures, fluids, electronics, optics, and digital twins. Our solutions help engineers accelerate design, reduce costs, and solve complex challenges across industries. From CFD to digital mission engineering, we deliver precision tools and expert support to turn your ideas into validated, high-performance products.

Client Speak

Hardik Bhutka

Design Engineer, Midwest Energy

“We are using Ansys Structural to do Modal analysis and Thermal Analysis (Using Fluent) of battery packs . We got to understand how the design will perform in testing at ARAI and in actual conditions . On Modal analysis Chaitanya sir guided us very well so we were able to finish the simulation faster. The Thermal simulation me and the ANSYS team are working on currently”